Vince Beiser is an award-winning journalist and author. He has reported from over 40 countries on assignments for Wired, the Atlantic, the Economist, the New York Times, and many other publications. His first book, The World in a Grain, was a finalist for the PEN / E. O. Wilson Literary Science Writing Award and California Book Award.

What’s the big idea?

Every promising solution comes with tradeoffs, and electric cars are no different. EVs remedy the carbon pollution of gas-fueled vehicles, but supply chains for the critical metals used in their production (as well as those of solar panels, wind turbines, and other electronics) present a new set of problems. Reducing consumption is still critical, even when choosing renewable energy.

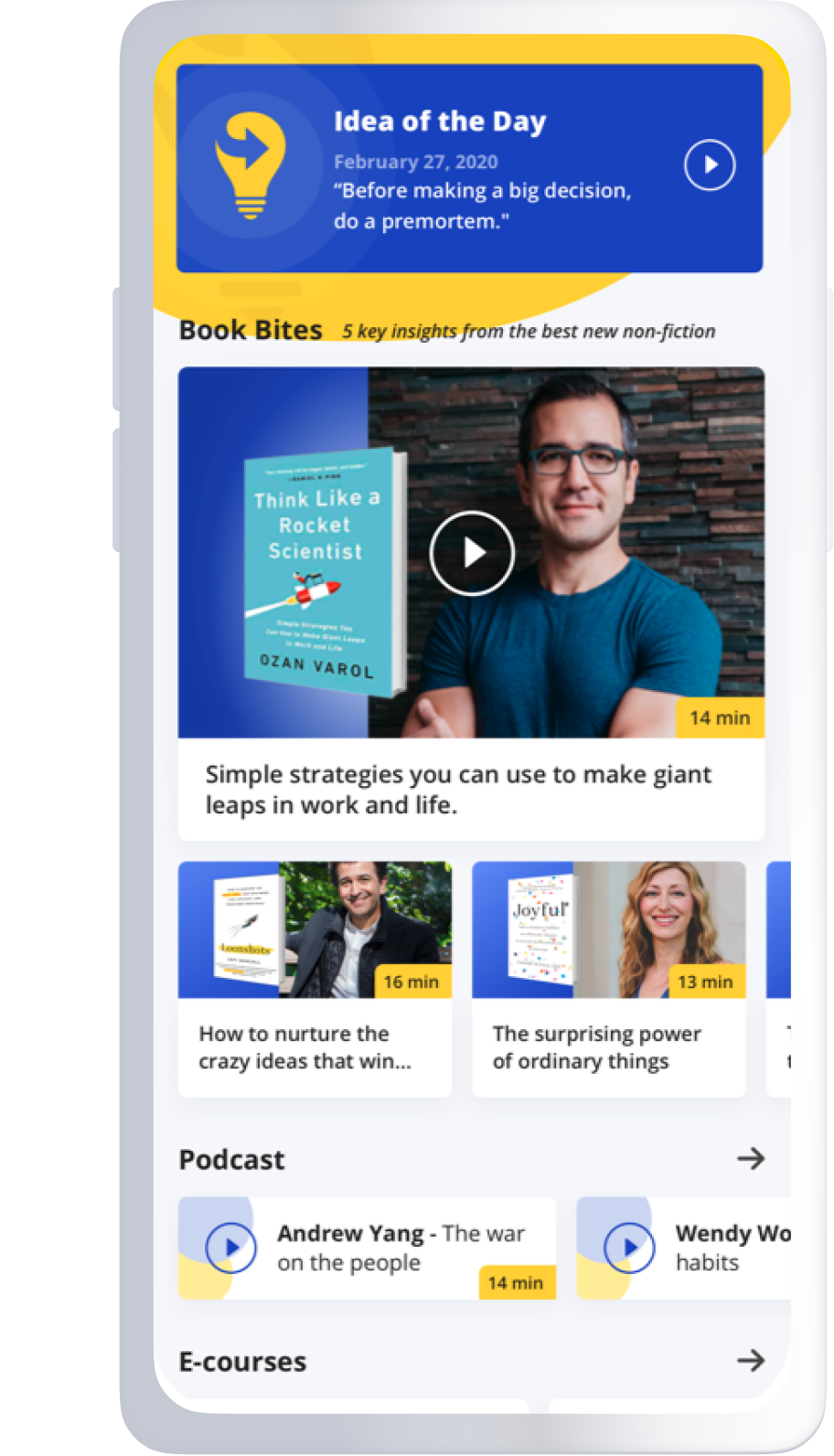

Below, Vince shares five key insights from his new book, Power Metal: The Race for the Resources That Will Shape the Future. Listen to the audio version—read by Vince himself—in the Next Big Idea App.

1. Electric cars are good for the climate but hard on the Earth.

I bought my first all-electric car, an unglamorous Nissan Leaf, in 2018. Man, did I feel virtuous. There I was, doing my part to save the Earth! My car didn’t emit any climate-changing carbon. But I do a lot of reporting about the unseen supply chains that make our modern lives possible. I started looking into where the materials for my car had come from and was horrified by what I found.

To get the lithium, cobalt, nickel, and other metals required to build electric cars like my Leaf, rainforests are being cut to the ground. Rivers are being poisoned. Children are being put to work in mines. Warlords are getting rich. And untold numbers of people are getting killed. While driving my electric car didn’t generate any carbon emissions, manufacturing my car certainly did damage to the planet and to people.

And it gets worse. That same basket of what are often called critical metals is used to build not only electric cars but also the hardware of renewable energy: solar panels, wind turbines, and the electric grid itself. Many of those critical metals are also in our digital gadgets, from iPhones to Xboxes.

All told, manufacturing all the electric cars, renewable energy infrastructure, and electronics we’ll need in the coming decades will require billions of tons of metals—in some cases, more than we’ve used in all human history. That means a whole lot of destructive, polluting, carbon-belching mining and refining of metals. The transition to renewable energy entails a paradox. We must do everything we can to stave off the catastrophes of climate change—but in doing so we may create a whole other set of catastrophes.

2. China is way ahead in the race for critical metals.

The supply chains for every single one of the metals we need for the energy transition and digital technology are all dominated to one extent or another by a single country: China. Leveraging its natural resources, relatively lax environmental standards, diplomatic clout, and shrewd overseas investments, China has, in recent decades, become the world’s leader in producing critical metals and the products they are used for.

China has huge domestic reserves of many metals (some of which it allegedly mines with forced labor). The resources it lacks at home are bought abroad; Chinese companies own mines worldwide that produce raw cobalt, nickel, and many other metals. Regardless of where critical metals are dug up or by whom, most will be sent to China for refining and processing. Chinese factories turn those refined metals into most of the world’s solar panels, wind turbines, and batteries for electric cars and consumer electronics.

“Regardless of where critical metals are dug up or by whom, most will be sent to China for refining and processing.”

All of which gives Beijing not only major economic power but also enormous geopolitical clout. And they have shown they are willing to use it. In 2010, China and Japan got into a spat over their territorial waters. To punish Japan, China cut off exports of rare earths, a set of metals crucial to Japan’s consumer electronics industry. The move sent shockwaves around the world. It was the opening shot in the global struggle for critical metals, when Western policymakers and corporate executives suddenly realized how vulnerable they were and how much leverage Beijing had over them. China could unsheathe the embargo weapon again at any time.

3. Everything has a cost.

How can we solve these problems connected with critical metals? Can we recycle more instead of digging them up?

Well, here’s a story about recycling. In my reporting for Power Metal, I spent some time with electronic waste scavengers in Lagos, Nigeria. Thousands of people earn their living scrounging up dead cell phones, laptops, and other gadgets, cracking them open with hammers or screwdrivers, and pulling out the little bits of copper, gold, and other valuable metals inside. Those bits of recovered metal get sold to middlemen and eventually wind up on a diesel-burning cargo ship, which carries them across thousands of miles of ocean to an industrial smelter in China or Europe, where they will finally be melted down and recycled.

Meanwhile, the other components of those phones and laptops—plastic, cables, screens—end up dumped or burned in the open, spreading incredibly toxic smoke into the lungs of whoever lives nearby. Everyone loves the idea of recycling, but what I saw in Lagos is what it often entails in practice. Recycling requires lots of energy, emits pollution, and is often done on the backs of the poorest people on Earth.

To be clear, recycling metal, even in the way I’ve just described, is generally easier on the planet than digging fresh virgin metal out of the ground. It is a good thing to do. But like everything, it comes with its own costs. There are no solutions, technologies, or social or economic developments that only bring benefits. Every development, however positive, also has some downside. The shift to renewable energy will ultimately benefit most people, but it will impose a steep price on some. The challenge we face is figuring out how to keep those costs to a minimum.

4. We can do better than recycling.

We tend to think of recycling as the best alternative to using virgin materials—but in fact, it’s one of the worst. Recycling is the most difficult and energy-intensive way to get further use out of just about any given product. Think about a glass bottle. To recycle it, you have to smash it to pieces, melt the crushed bits down, and shape them into a new bottle. It’s a whole industrial process that requires a lot of energy, time, and expense. Or you could just wash out the bottle and reuse it.

“We could and should repair, refurbish, and resell many more electronic gadgets.”

Similarly, scrapping an old phone, car battery, or solar panel and processing it back down to metals requires far more effort, energy, and expense than refurbishing that product to be used again. We already do some of this—you can buy refurbished computers, phones, and solar panels online. But it’s mostly happening in the developing world. A huge electronics repair industry exists across Africa, Asia, and Latin America. In North America, the default tends to be that when a cordless vacuum or cell phone breaks, we chuck it and get a new one.

We could and should repair, refurbish, and resell many more electronic gadgets. It’s good for the planet and your wallet. Refurbished products are almost always cheaper than brand-new ones. It all goes back to that slogan from the 1970s: Reduce, Reuse, Recycle. But we tend to read it backward these days.

5. Using less is best.

The number one way individuals can do something about the problems caused by the race for critical metals is not to buy a car. Not even an electric one. Cars are by far the most energy- and resource-intensive thing most of us own, aside from our homes.

Now, I am not saying we should ban cars. I am not saying you’re a terrible person if you own a car. I own a car. But here’s the thing: I used to live in Los Angeles with my wife and two kids, and we had two cars. We needed them to get everyone to work, school, and the grocery store. But a few years ago, we moved to Vancouver, Canada, and immediately got rid of one of those cars. Over the last couple of decades, Vancouver has been redesigned so that people can get around easily and safely on foot, bicycle, or by public transit. We didn’t need that second car anymore.

There are more than a billion fossil fuel-powered cars on the roads today; if we exchange every one of them for an electric car, we’ll swap one set of problems for another. We need to switch to electric cars: on balance, they are less harmful than gas-powered ones. But if we can switch to electric vehicles while also reducing the total number of cars out there, we will save energy and resources, benefiting all tremendously. On top of the environmental upsides, there are personal ones: not having to pay for, park, insure, and maintain that second car has removed a major expense and source of stress in my life.

Our choices about where and how we get the critical metals that will enable the energy transition and how much of them we really need are tremendously important. Every choice will entail a cost, but some will cost much more than others. The best approach is to work toward a world where we maintain our quality of life while consuming less energy, less metal, and less of just about everything—even electric cars.

To listen to the audio version read by author Vince Beiser, download the Next Big Idea App today: